Techtextil North America, a trade show for textiles and nonwovens, created a space for industry innovators to come together, share new ideas, learn about latest products, and network with others to expand their business ventures. This event, which took place Aug. 23 to 25, provided great potential for industry leaders to collaborate and strengthen their businesses.

Techtextil North America also offered educational sessions, many of which were centered around the idea of sustainability. Two of these such sessions were titled “Sustainability Strategies to Protect Your Brand and Your Bottom Line,” and “Sustainability in Laundering and Textile Care.” The speakers represented businesses such as Procter and Gamble, Cintas and Hohenstein Institute.

Hemp fiber non-woven matting.

Multiple businesses were represented at this trade show, from fabric sellers looking for cloth, weavers looking for yarn and spinners looking for cottonized hemp to spin into yarn. While cotton and hemp are natural fibers, cotton requires more land and pesticides to grow than hemp does, meaning that cottonizing hemp provides a similar, if not superior, fiber that is better for the environment and more sustainable.

IND HEMP showcased hemp fiber, presenting it as a potential component to woven and non-woven textiles. Within the textile industry, many textiles offered are synthetic. Hemp fiber is a strong and durable natural fiber, making it a great addition to countless products. It increases the strength of other products and is reemerging as a sought-after component.

Montana Department of Agriculture marketing representative Weston Merrill listens as Dr. Andre West, director of the Zeiss Textiles Extension Center explains the equipment and process for spinning cotton and how hemp must look and perform to work in these processes.

IND HEMP displayed hemp fiber to introduce more textile industry leaders to the product. With their 52,000 square foot fiber facility in Fort Benton, MT, IND HEMP can process hemp into several different kinds of hemp fiber utilizing their five ton per hour Laroche fiber decortication line. The applications for hemp fiber are innumerable. By providing hemp to textile industries, IND HEMP hopes to bring hemp fiber to traditional markets, making products higher quality and utilizing a sustainable crop.

Hemp was brought to the Techtextil North America show by IND HEMP and BastCore. BastCore is a leader within the hemp fiber world, and IND HEMP congratulates them on being the first company to market with U.S. grown and processed hemp. By cottonizing hemp and producing hemp fiber products, BastCore creates products that are spun into yarn and woven into denim to make jeans – all of which is done in the U.S.

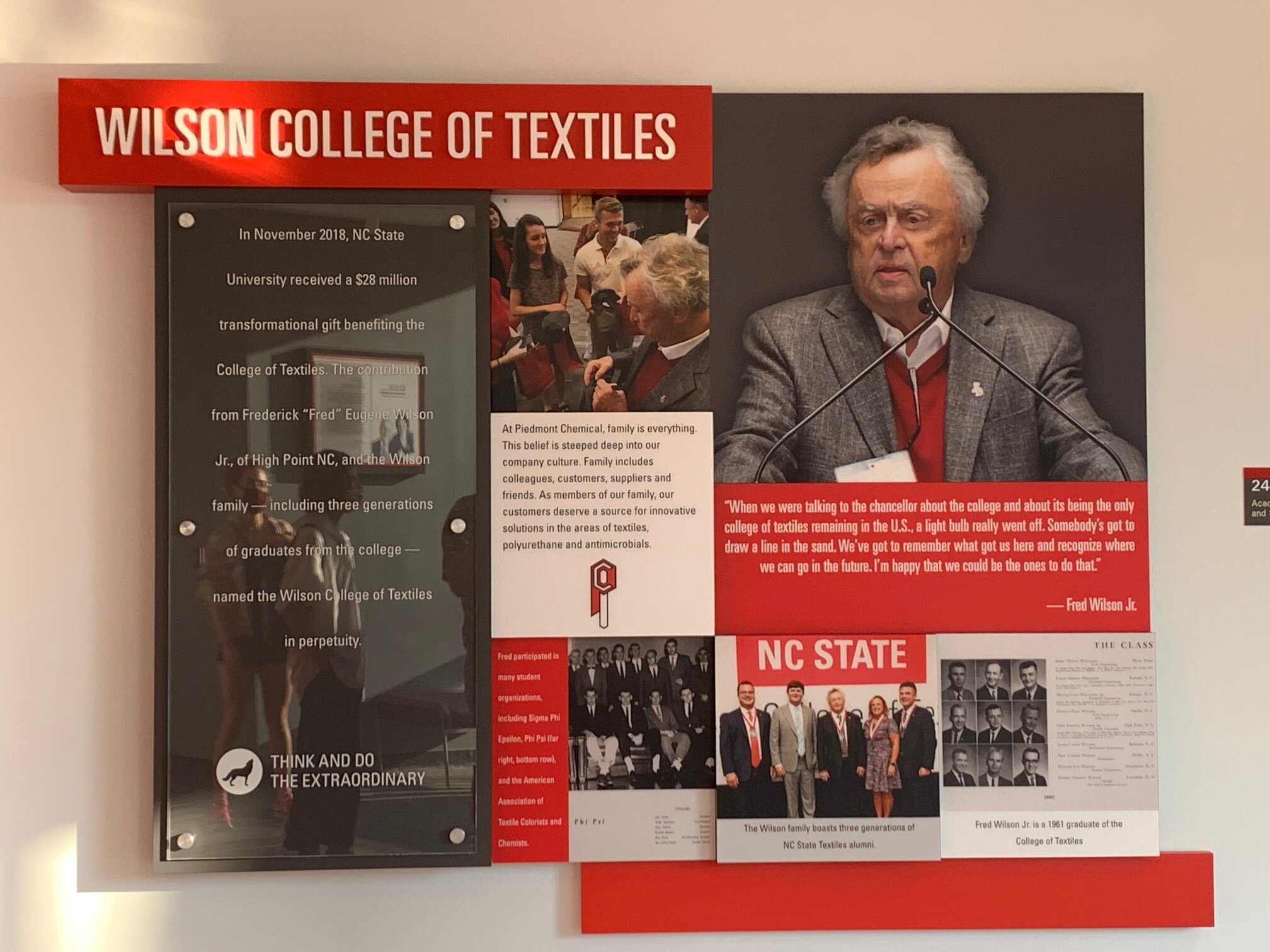

North Carolina State Wilson College of Tetiles and Zeiss Textile Extension Lab educated attendees about cottonizing hemp.

Cottonizing hemp simply means the hemp fiber is cut and softened to replicate cotton. Equipment used for processing cotton require the fibers to be 1.5” and soft. There are many options to cottonize hemp, including mechanical and chemical processes. IND HEMP was joined by the Montana Department of Agriculture marking representative, Weston Merrill, who coordinated a visit to North Carolina State Wilson College of Textiles and Zeiss Textile Extension Lab to learn more about the hemp cottonizing process.

Steve Bernier, director of sales at IND HEMP, and Guy Carpenter, president of Bear Fiber.

Companies like Bear Fiber in North Carolina cottonize U.S. grown hemp fibers to imitate cottonseed, which can then be spun and used to make products like hemp socks. Guy Carpenter, president of Bear Fiber, understands the entire hemp fiber process from field, decortication, cleaning, carding, cottonizing, spinning and knitting. Bear Fiber takes hemp fiber, cottonizes it, and moves it through the entire process to become a well-made hemp sock.

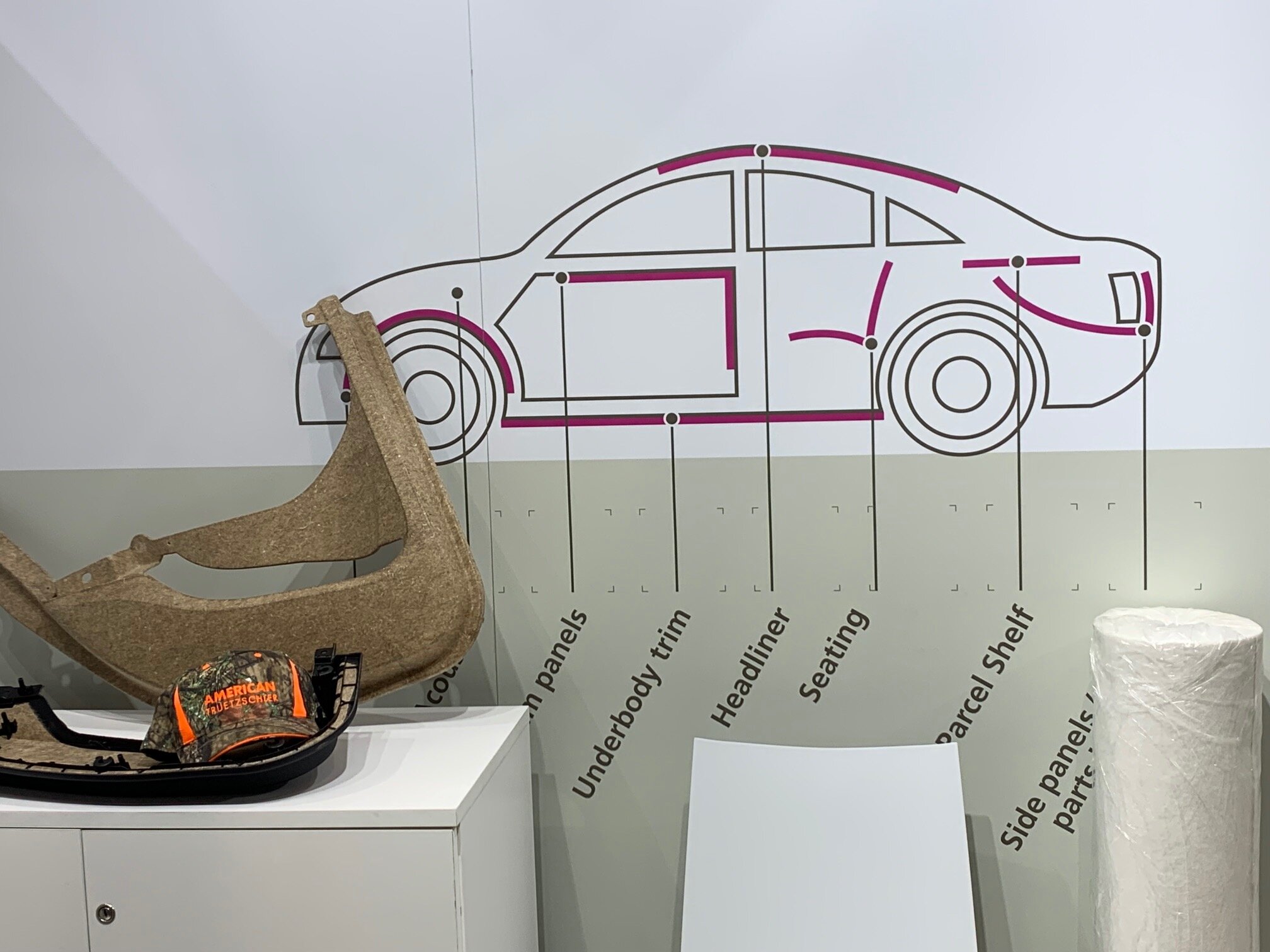

In addition to woven markets, hemp is also a strong contender for non-woven fibers. Opportunities for nonwovens include insulation and building materials, disposable wipes and matting used to produce other biocomposites. Non-woven hemp fiber can be used in biocomposites to make car parts, including door panels and dashboards.

Hemp fiber nonwovens are already being used to manufacture multiple parts for the auto industry in the U.S., as exhibited here by Polyviles.

Using hemp as a non-woven building material includes processing hemp into a wool-like material that is used for insulation. Hempitecture creates an insulation product called HempWool, a product made with natural materials designed to replace conventional, toxic insulation materials.

The opportunities for hemp in the textile industry are abundant and exciting. With IND HEMP’s fiber decortication facility opening in 2021, the U.S. will gain another American-based hemp fiber processing facility, paving the way for increased use of a natural, American-made and sustainable product. Hemp fiber has countless opportunities in the world of woven and non-woven textiles. A natural fiber, hemp is functional, durable and breathable, all of which present hemp as a great component to sustainable textiles.