Hemp building materials are proving to be a promising alternative to traditional building materials. Processing hemp into hemp fiber-based products allows for new, innovative ways of building homes that are sustainable, durable and healthy. Compared to traditional methods of home building, hempcrete and hemp fiber insulation offer several qualities that take the lead in terms of the best building products overall.

Hempcrete is a biocomposite material mixed with lime to create a long-lasting and healthy alternative to traditional concrete. Hempcrete allows for high levels of insulation while remaining permeable. The material is lightweight, yet rigid and durable. While hempcrete is a promising alternative to concretes, it is generally limited to a two-story house as it is not excessively load-bearing. It also takes over a month to fully dry, making it difficult to use in rainy locations.

Hempcrete

Hempcrete is a biocomposite material mixed with lime to create a long-lasting and healthy alternative to traditional concrete.

With the proper project, location and timing, hempcrete is a great option for building homes. Traditional construction contributes greatly to pollution and has a large carbon footprint. The materials themselves, along with the energy needed for transportation, are detrimental to the environment. These typical materials are also hazardous and toxic. Hempcrete, while showcasing different challenges, is worth pursuing if only for the health of the builders and the environment. As a carbon-negative material, hempcrete absorbs carbon dioxide from the air as it dries, meaning it cleans the air rather than contributes negative carbon emissions to the atmosphere.

Because hemp is a natural building material, it is becoming a leader in the building industry for those who wish to have a low carbon footprint. Using hempcrete is much more environmentally friendly and maintains strength and durability. Naturally resistant to pests, fungus and fire, hempcrete also offers sound insulation. Overall, hempcrete offers incredible building applications as it is sustainable, cost-effective and environmentally friendly.

Just as hempcrete shows promise in the building industry, hemp fiber is proving to be a superior insulation option. Hemp fiber used as insulation in homes insulates extremely well for both heat and sound. This means reducing energy demands in the home and, overall, lowering the cost of heating the home.

Hemp displayed in the varying processing stages, including hemp fiber (far left). Hemp fiber used as insulation is a non-toxic alternative to traditional home insulation.

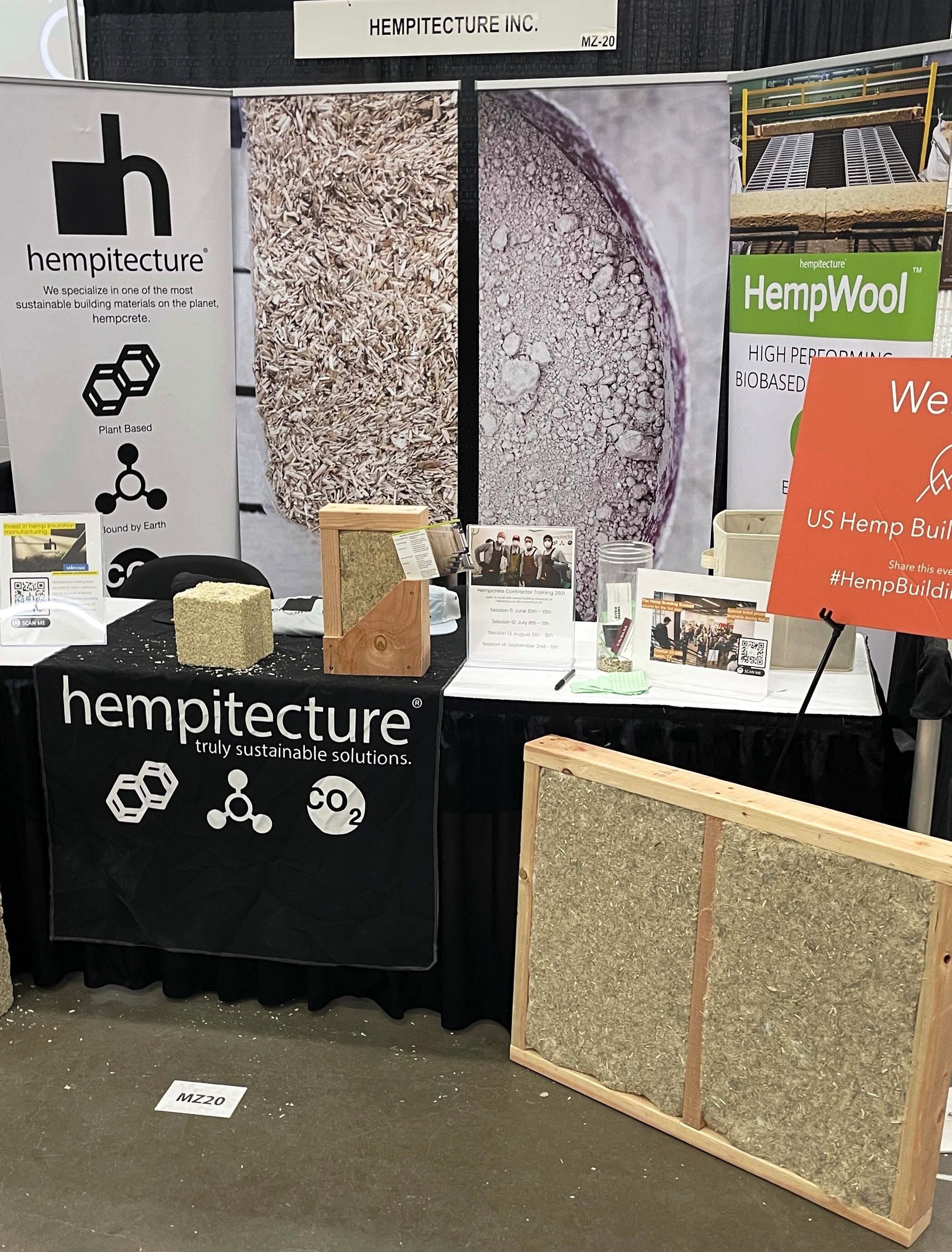

Hemp insulation can be found at several companies, including Hempitecture, and is known as HempWool. It is a fiber batt insulation product that is sustainable, hypoallergenic, high-performing and has a low carbon footprint. HempWool is able to store heat and save energy. It is easy to install in homes and is non-toxic, making it a great alternative to traditional toxic insulation materials.

Using hemp as a building material means using a product that is naturally resistant to fires and insects. Not only does it offer higher quality protection, but using hemp allows for breathable homes and walls that positively affects the air quality within the home.

Hempitecture products, such as hempcrete and hemp fiber, on display at the NoCo Hemp Expo. March 2021.

In addition to hempcrete and hemp fiber proving to be better building materials for the environment, the process of growing hemp is also better for the environment. Hemp can be grown and harvested much faster than trees. This means quicker access to building material, leading to less demand for lumber, which in turn will lessen deforestation. Hemp provides four times as many fibers per acre than trees. It grows quickly and easily in most climates, making it easy to grow abundantly and use its products effectively.

Hemp building materials are superior since they have lower carbon emissions, are non-toxic products, and provide great benefits such as breathability and pest and fire resistance, all while remaining strong and durable. Hempcrete and hemp insulation prove to be better for the environment, better for those building the homes and better for those living in the hemp-based home.