Industrial Hemp!

Why? Hemp fiber is the perfect starting point to connect “eco” with industry. It can be grown without pesticides or herbicides; plus, its wood core can supplant trees in several industrial applications, all while sequestering CO2 into the soil and usable goods.

40% of all greenhouse gas emissions are generated by built environments. This is a larger footprint than any other sector.

Hemp requires much less water than similar crops, and is ready to harvest in as early as 100 days after planting.

Hemp sequesters 9 TONS of CO2/acre during it’s growing season.

Domestically grown. We stimulate local economies, while helping manufacturers avoid overseas shipping delays, reducing transportation costs, and eliminating tariff concerns.

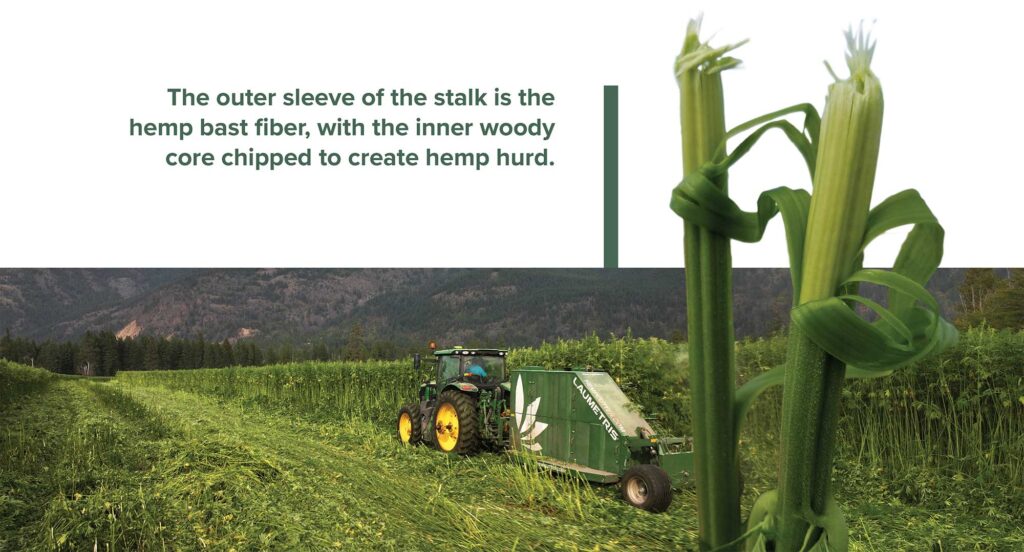

The Anatomy of a Material That Matters

Our natural fibers are ideal for polymer composites, absorbent applications, thermal & acoustic insulation. IND HEMP fiber products are rapidly renewable and a readily available alternative source of material for a wide range of needs and industries.

Countless Possibilities

Hemp-based products offer practical, sustainable solutions for a wide range of applications in the built environment. This booklet introduces the possibilities of hemp and showcases it as the emerging key resource in environmentally responsible construction.

Residential

Housing

Landscape & Garden

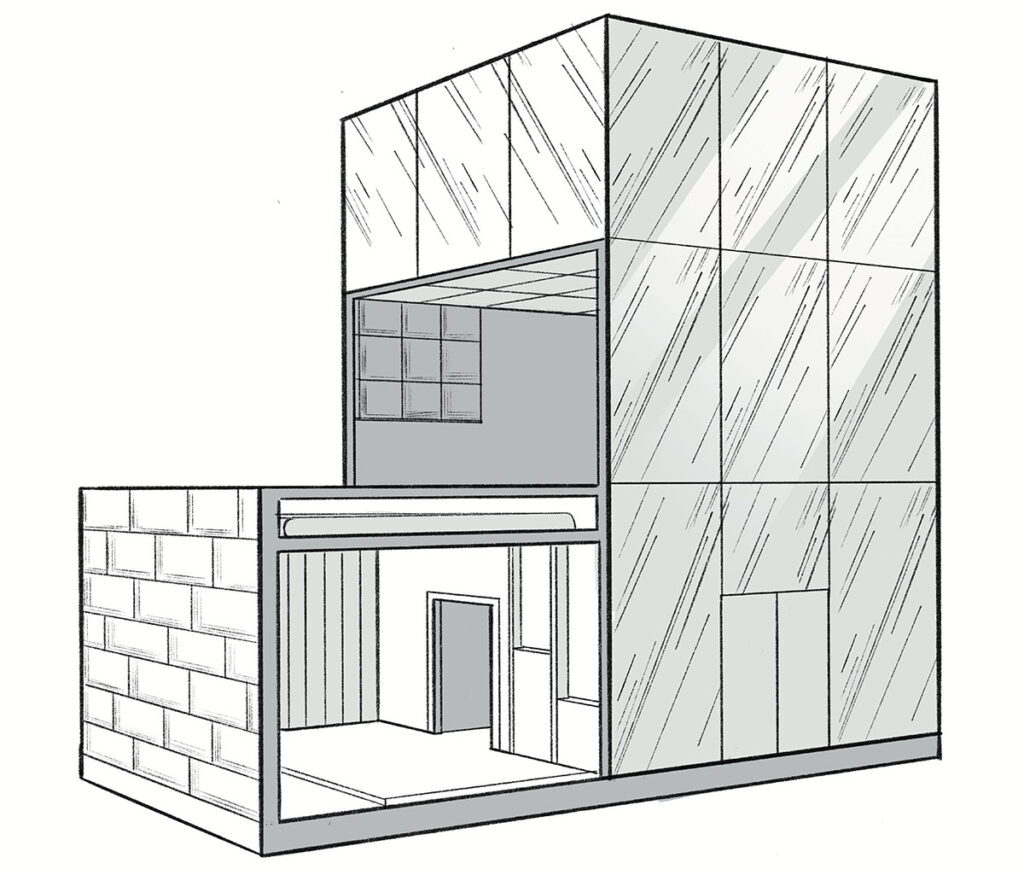

Commercial

Business & Public

Orchard and Nursery

Civil & Restoration

Infrastructure

Land & Forest Reclamation

Industrial

Manufacturing

Oil Drilling & Gas

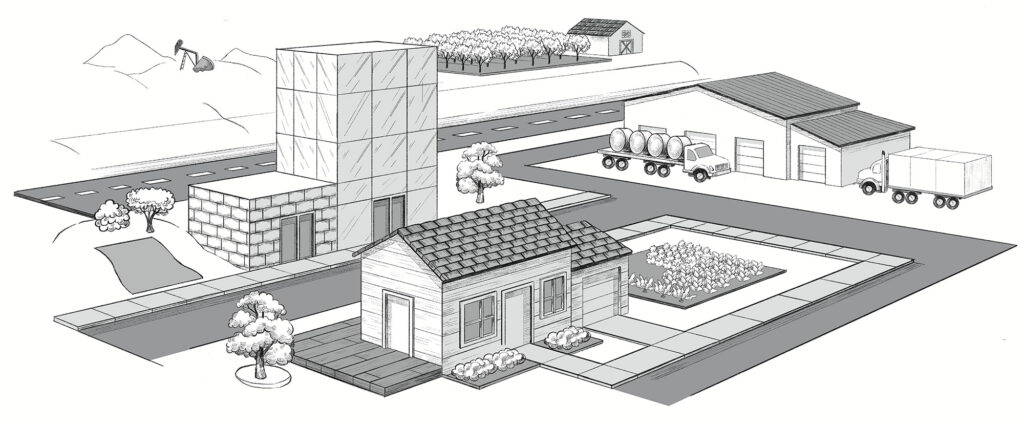

Residential Applications

In residential settings, hemp enhances comfort and sustainability. Durable, breathable, and biodegradable, these products improve indoor air quality and soil health while reducing dependence on imported or synthetic materials.

HOUSING

- • Batt Insulation

- • Blow-in Insulation

- • Carpet Underlayment

- • Flooring

- • Hempcrete Cast in Place

- • Precast Blocks

- • Structurally Insulated Panels (SIPs)

- • Biocomposite decking & lumber

- • Shingles

- • Extruded Window Frames

- • Rigid Insulation Board

LANDSCAPE & GARDEN

- • Weed Barrier

- • Mulch Mat

- • Mulch

- • Garden Squares

- • Tree Rings

- • Hydromulch

- • Microgreens

- • Seed Starter

Commercial Applications

In commercial construction and agriculture-adjacent industries, hemp delivers high performance and sustainability. From acoustic panels in office buildings to sustainable ground cover in vineyards, nurseries, and orchards, hemp’s versatility supports low-carbon operations and regenerative land practices.

BUSINESS & PUBLIC

- • Acoustic Panels

- • Ceiling Tiles

- • Architectural Wall Panels

- • Batt Insulation

- • Blow-in Insulation

- • Flooring

- • Hempcrete Precast Blocks

- • Structurally Insulated Panels (SIPs)

ORCHARD & NURSERY

- • Mulchmat blankets

- • Weed Barrier

- • Tree Rings

- • Garden Squares

- • Mulch

- • Biochar

Civil & Restoration Applications

Civil engineers and contractors are turning to hemp-based solutions for erosion control, storm water management, and environmental protection. Hemp fiber offers strength, water absorbency, and biodegradability—making it ideal for erosion-control blankets, sediment control wattles and silt fences, used in highway, bridge, and land reclamation projects.

INFRASTRUCTURE, LAND & FOREST RECLEMATION

- • Hydromulch

- • Silt Fence

- • Erosion Control Blankets

- • Wattles

- • Mulch Mat

Industrial Applications

Hemp’s natural fibers bring performance and sustainability to industrial manufacturing during site construction and daily operations. From construction materials to environmental protection—hemp absorbents outperform synthetics for oil and chemical cleanup, while products that integrate hemp fibers increase performance and reduce carbon footprints.

MANUFACTURING

Site Construction:

- • Acoustic Panels

- • Ceiling Tiles

- • Architectural Wall Panels

- • Batt Insulation

- • Blow-in Insulation

- • Flooring

- • Hempcrete

- • Precast Blocks

- • Structurally Insulated Panels (SIPs)

- • Hydromulch

- • Silt Fence

- • Erosion Control Blankets

- • Wattles

- • Mulch Mat

Operations:

- • Mat absorbents

- • Particulate absorbents

DRILLING & GAS

Site Construction:

- • Hydromulch

- • Silt Fence

- • Erosion Control Blankets

- • Wattles

- • Mulch Mat

Operations:

- • Loss Circulation Materials (LCM)

- • Well capping Additives

- • Mat absorbents

- • Particulate absorbents

Hemp is Here.

Hemp isn’t the future of building — it’s the present. Across North America, innovators are proving that hemp-based materials deliver strength, efficiency, and sustainability that rival or surpass conventional options. From insulation and structural panels to flooring and erosion-control systems, these brands are already redefining what’s possible with nature’s most versatile fiber.

1. Hempitecture — HempWool® insulation, plant panels, and building systems

2. HempWood — Sustainable hardwood flooring and panel products

3. Homeland Hempcrete — Prefabricated hempcrete SIP panels

4. Americhanvre — On-site spray-applied hempcrete construction

5. Renewabuild — Structural hemp blocks for walls and thermal mass

6. IND HEMP — Hemp fiber erosion-control blankets and natural landscape solutions

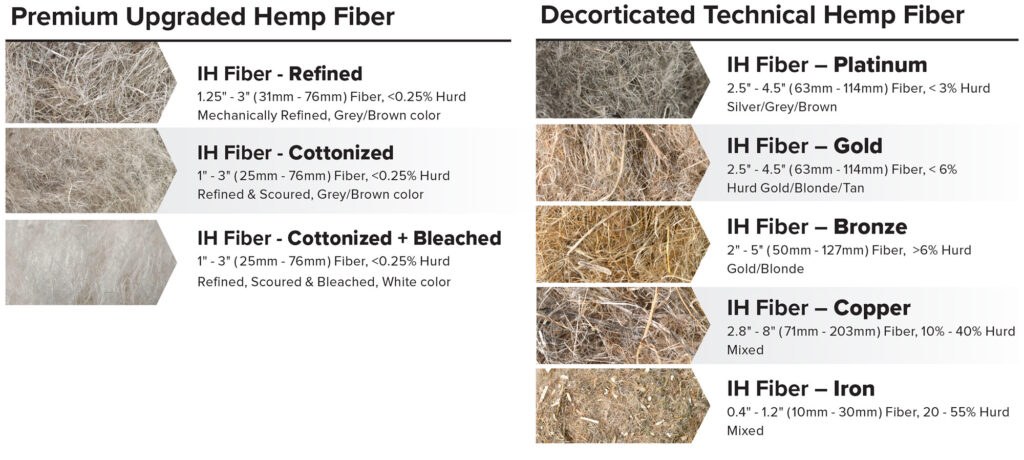

Raw Materials for Your Next Generation of Building Products

Premium & Technical Fiber

IND HEMP’s premium and technical hemp fibers are made in Montana and refined for performance. Using advanced mechanical and wet-processing methods, our fibers are opened, cleaned, and carded to create consistent, high-quality natural material ready for nonwovens, textiles, and composites. Strong, lightweight, and renewable, these fibers bring durability and sustainability to modern manufacturing.

Particulates & Fiber Hurd Blends

Our hemp hurd and fiber blends are low-density, absorbent, and ideal for sustainable building and industrial products. Available in custom sizes and blends, they deliver strength, porosity, and moisture control for applications such as concrete additives, molded panels, absorbents, and erosion-control media—all sourced and processed in Montana.

We’re Ready When You Are.

IND HEMP operates a full-scale industrial hemp fiber processing facility, equipped to decorticate hemp stalks into high-quality bast fiber and hurd. With established logistics and production systems, we supply raw materials for a wide range of applications including textiles, biocomposites, erosion control, and sustainable construction.

Our fiber products are already supporting manufacturers across North America and beyond, demonstrating our capacity to meet commercial demand at scale.

How are you advancing your sustainable solutions? We’d love to hear from you!