The global construction sector stands at a technical and economic inflection point. Buildings—and everything required to construct, maintain, and operate them—now account for 40% of all global greenhouse gas emissions. That footprint is larger than transportation and agriculture combined, and it continues to grow as urbanization rises and material demand accelerates.

Against this backdrop, the industry is under unprecedented pressure to transition to low-carbon, high-performance, renewable, and circular materials. Regulations, customer demand, and investor expectations are shifting simultaneously, creating a market landscape where sustainability is no longer optional—it is foundational to competitiveness, risk management, and brand equity.

At the center of this shift is a material that the world is finally ready to embrace at scale:

Industrial hemp.

What was once considered an “alternative” crop is now emerging as one of the most practical, scalable, and impactful feedstocks for a decarbonized construction economy. And the momentum is not speculative—leading manufacturers, designers, and governments are now integrating hemp-derived materials into specifications, procurement frameworks, and R&D portfolios.

Why Hemp? A Scalable Material Platform for a Carbon-Constrained World

Industrial hemp is uniquely positioned to solve critical challenges in the built environment—from embodied carbon reduction to supply chain resilience to cost-effective performance enhancement.

A Carbon-Negative Material at the Farm Gate

Few crops can match hemp’s climate performance. During its rapid 100–120 day growing cycle, hemp captures up to 9 tons of CO₂ per acre—one of the highest sequestration rates per acre for any commercially grown plant. Page 2

This carbon is then locked into:

· Fiber (for insulation, textiles, biocomposites)

· Hurd (for hempcrete, animal bedding, soil amendments)

· Biochar (a stable carbon sink with soil and industrial applications)

These attributes make hemp one of the rare materials that is inherently carbon-negative before manufacturing even begins.

Low Input Requirements, High Agronomic Efficiency

Unlike water-intensive row crops, hemp requires less water and can be grown without pesticides or herbicides. It thrives in diverse climates and regenerates soils through dense canopy shading and deep root systems. Page 2

This provides a repeatable, reliable, and environmentally superior alternative to traditional timber and petrochemical feedstocks.

Domestic Supply Chain Security

Hemp is a U.S.-grown, U.S.-processed material. As noted in the PDF, local sourcing reduces costs and eliminates exposure to tariffs, volatile global shipping costs, and overseas supply interruptions. Page 2

For manufacturers aiming to localize production or meet new federal “Buy Clean” procurement criteria, hemp offers a powerful path forward.

Hemp Across the Built Environment: Applications That Already Exist Today

Industrial hemp is not theoretical. It is already deployed across multiple categories of residential, commercial, civil, and industrial construction.

Below is a deeper exploration of these categories.

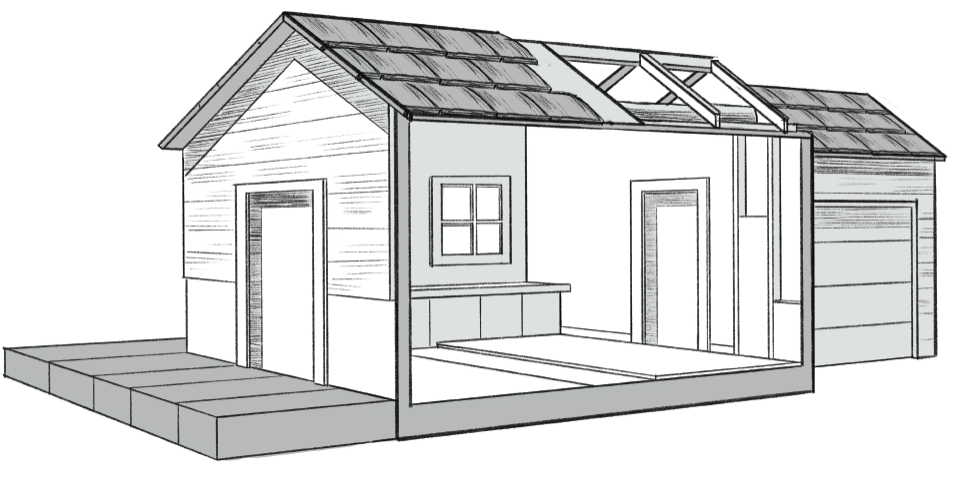

Residential Construction: Reimagining the Materials That Shape Our Homes

Residential builders face mounting pressure to reduce embodied carbon while improving indoor air quality, energy efficiency, and climate resilience. Hemp-derived materials directly address these concerns.

Building Envelope Solutions

Batt insulation and blow-in insulation made from hemp fibers provide:

· High R-values

· Superior moisture regulation

· Mold resistance

· Natural breathability

· Zero VOC emissions

This improves energy performance while reducing health risks associated with fiberglass and synthetic materials.

Interior Comfort and Surface Materials

Hemp-based carpet underlayment, flooring substrates, and acoustic panels enhance comfort, air quality, and acoustic performance.

Hempcrete Construction

Hempcrete—using the hurd as aggregate—is gaining adoption in cast-in-place and precast formats:

· Cast-in-place hempcrete creates breathable, high-insulation monolithic walls.

· Precast hempcrete blocks accelerate construction timelines and reduce labor costs.

These systems offer exceptional fire resistance, thermal inertia, and indoor air quality benefits.

Advanced Building Systems

Structural Insulated Panels (SIPs) and rigid insulation boards using hemp fiber represent the next generation of high-performance building envelopes.

Residential Landscaping & Gardening: Natural Alternatives to Plastics

The landscaping industry is under increasing scrutiny for plastic netting, non-degradable weed barriers, and synthetic mulches. Hemp-based solutions offer biodegradable, high-performance alternatives such as:

· Weed barriers

· Mulch mats

· Tree rings

· Seed starters

· Hydromulch

These products naturally integrate into the soil without leaving microplastics—a key differentiator in sustainability-driven markets.

Commercial Construction: Scalable Solutions for Large Buildings and Public Infrastructure

In commercial applications, hemp provides performance and sustainability without compromising compliance.

Key applications include:

· Acoustic panels

· Ceiling tiles

· Architectural wall panels

· Flooring

· Blown-in insulation

· Hempcrete precast blocks

· SIPs

As ESG reporting intensifies and corporations target embodied carbon, these applications are taking center stage in procurement decisions.

Orchards, Nurseries & Agriculture Commerce

The commercial agricultural sector is adopting hemp-based:

· Mulch blankets

· Tree rings

· Mulch

· Biochar

· Weed barriers

These products reduce operational labor, improve soil regeneration, and eliminate the need for petroleum-based alternatives.

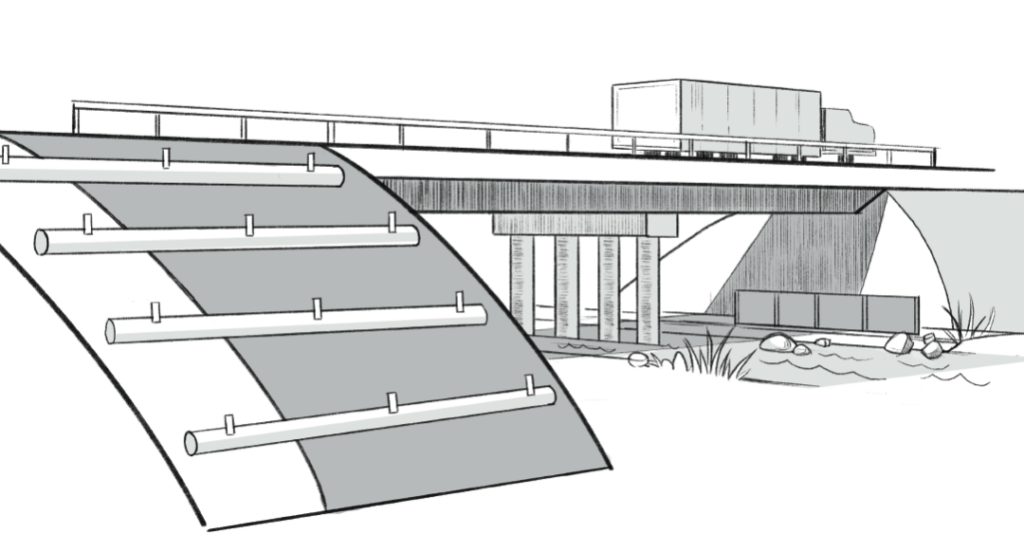

Civil, Environmental & Restoration Markets

Climate resilience and infrastructure upgrades are federally funded priorities. Hemp plays a vital role in:

· Hydromulch

· Erosion control blankets

· Silt fencing

· Wattles

· Mulch mats

These products address erosion, slope stabilization, post-fire restoration, and watershed protection—current critical needs in many Western states.

Industrial and Manufacturing Applications

Hemp’s industrial footprint is expanding rapidly due to its absorbency, strength, and compatibility with composite manufacturing.

Construction & Operational Use

· Acoustic panels

· Ceiling tiles

· SIPs

· Architectural wall panels

· Flooring

Site Operations

· Hydromulch

· Silt fence

· Absorbent mats

· Spill particulate absorbents

Oil & Gas

Even extractive sectors are adopting hemp for:

· Loss circulation materials (LCM)

· Well-capping additives

· Absorbents

This demonstrates hemp’s cross-industry versatility.

The Broader Impact: Why Industrial Hemp Represents a Systems-Level Opportunity

Industrial hemp is not simply a new material—it is a platform for regenerative manufacturing and carbon-smart construction.

Economic Impact

Hemp reconnects rural American agriculture with domestic manufacturing. Farmers grow it; processors refine it; manufacturers convert it; builders install it.

Environmental Impact

- Carbon-negative feedstock

- Biodegradable end-of-life profiles

- Reduced reliance on plastics

- Soil regeneration via deep-root systems

- Lower transportation emissions through local sourcing

Market Transformation

Hemp supports:

- LEED, WELL, and Living Building Challenge credits

- ESG-aligned procurement

- Buy Clean policies

- Net-zero strategies

- Resilience and circularity goals

No other material offers this combination of performance, environmental benefit, and supply chain feasibility.

How Will You Advance Sustainable Solutions?

“How are you advancing your sustainable solutions?”

For industrial stakeholders—architects, engineers, city planners, contractors, developers, and sustainability leaders—the question is more than inspirational. It is strategic.

The transition to a low-carbon, high-performance building marketplace is underway. The organizations that move early—those that redesign product lines, retool material portfolios, or begin specifying bio-based alternatives—will capture the economic, environmental, and reputational benefits first.

Industrial hemp is ready. IND HEMP is ready. The market is ready.

The only question left is: Who will lead?

We invite innovators, builders, manufacturers, and community partners to join us in accelerating this transformation.

Let’s build a better future—with the materials nature designed.

#BuiltEnvironment #SustainableConstruction #LowCarbonMaterials #EmbodiedCarbon #RegenerativeBuilding #BioBasedMaterials #CircularConstruction #HealthyBuildings #Hempcrete #EcoConstruction

IG: @INDHEMP