As global industries grapple with the urgent mandate to reduce their environmental footprint, the spotlight is increasingly turning toward nature-based, regenerative materials that can replace fossil-derived inputs. Among the contenders rising to meet this moment is industrial hemp—and more specifically, its bast fiber, which offers a compelling path toward low-carbon, high-performance nonwoven applications.

At IND HEMP, we believe hemp fiber holds transformative potential for the nonwovens sector—unlocking new pathways for lightweighting, plastic reduction, compostability, and renewable material sourcing across a wide array of products: from personal care wipes and filtration media to acoustic insulation and automotive composites.

This is your invitation to rethink what’s possible with nonwovens. And to partner with us to build the infrastructure, supply chain, and innovation ecosystem that makes it scalable.

The Industrial Shift: Nonwovens Demand Sustainable Disruption

Nonwoven fabrics are the silent enablers of modern life—essential to hygiene products, medical disposables, automotive interiors, filtration media, construction materials, and geotextiles. Traditionally dominated by synthetic polymers like polypropylene and polyester, this sector now stands at a crossroads.

With global regulations tightening around single-use plastics and consumer demand surging for eco-conscious alternatives, the nonwovens industry is under pressure to shift away from fossil-derived fibers—and toward biodegradable, renewable materials that deliver performance without compromising sustainability.

Enter hemp.

Performance Meets Planet-Positive Impact

Hemp bast fiber offers a rare combination of technical functionality and environmental benefit:

✅ Strength & Durability: Hemp’s natural tensile strength rivals synthetic fibers, enhancing mechanical performance in composites and reinforcing nonwoven webs in automotive, construction, and erosion control markets.

✅ Moisture Management: Hemp is highly absorbent and breathable—ideal for wipes, hygiene liners, insulation, and acoustic applications where wicking and moisture retention are critical.

✅ Lightweighting & Insulation: With lower density than mineral fillers or fiberglass, hemp contributes to lightweight yet durable structures—valuable in sectors like mobility, construction, and packaging.

✅ Regenerative by Nature: Hemp in best case scenarios can sequester up to 9 tons of CO₂ per acre, grows rapidly with low input requirements, and enriches soil health—making it a compelling feedstock for brands focused on decarbonization and circularity.

✅ End-of-Life Advantage: Hemp-based nonwovens, especially those free of synthetic binders, can be fully compostable or biodegradable, aligning with emerging EPR (Extended Producer Responsibility) frameworks worldwide.

Nonwoven Technologies Where Hemp Shines

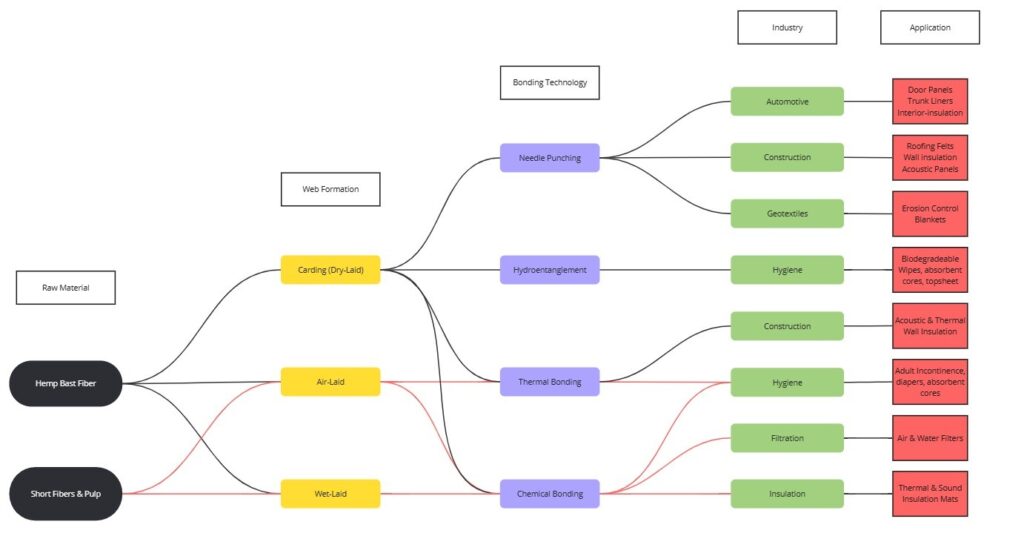

Through tailored processing and fiber preparation, hemp integrates seamlessly into multiple nonwoven manufacturing processes:

Needlepunched Nonwovens: 100% hemp felts (like some of IND HEMP’s products) are already in-market—biodegradable, binder-free, and high-performance for insulation, geotextiles, and automotive panels.

Spunlace (Hydroentangled): Hemp blends beautifully with cotton, viscose, or wood pulp to form soft, absorbent wipe substrates. Existing partners are proving that hemp-based wipes can meet commercial softness, strength, and biodegradability requirements.

Thermally Bonded Mats: When blended with bicomponent or bio-based thermoplastics, hemp forms the base for natural fiber composites (NFCs)—used in molded auto parts, acoustic panels, and high-loft insulation.

Air-Laid and Wet-Laid Nonwovens: Hemp pulp or micronized fibers can serve as fluff core alternatives in diapers, hygiene products, and molded packaging. Their water retention and porosity also make them candidates for filtration media and tea or coffee filters.

Industry Adoption: What’s Holding Hemp Back?

The question is no longer “Can hemp work in nonwovens?”—but rather, “How fast can we scale it?”

Some barriers remain:

- Fiber Supply & Processing: Uniformity, fiber cleanliness, and fiber length must be optimized for high-speed lines. IND HEMP and partners are investing in fiber decortication, cottonization, and quality control to ensure ready-to-run feedstock.

- Cost Competitiveness: Synthetic fibers are artificially cheap due to entrenched petrochemical infrastructure. But the true cost of plastic—from microplastic pollution to CO₂ emissions—is being internalized through regulation and ESG frameworks.

- Education & Specifier Awareness: Many R&D and sourcing teams are unaware of how far hemp has come in terms of quality and scalability. That’s why this is a call to action—to explore, trial, and validate.

Join the Movement Toward Sustainable Manufacturing

At IND HEMP, we’re not just selling fiber—we’re building an ecosystem of hemp innovation. From farm to fiber to finished good, we are enabling whole-plant utilization, circular value chains, and better agriculture practices.

Together, we can transition the nonwovens industry toward a more sustainable, resilient future. Let’s make materials that not only perform—but also protect the planet and the people who use them.

📩 Interested in learning more or accessing the full report? Send us a message or email [email protected] to start the conversation.

#IndustrialHemp #Nonwovens #SustainableMaterials #CircularEconomy #RegenerativeAgriculture #CarbonReduction #CompostableWipes #HempInnovation #GreenManufacturing #BiobasedSolutions

IG: @indhemp